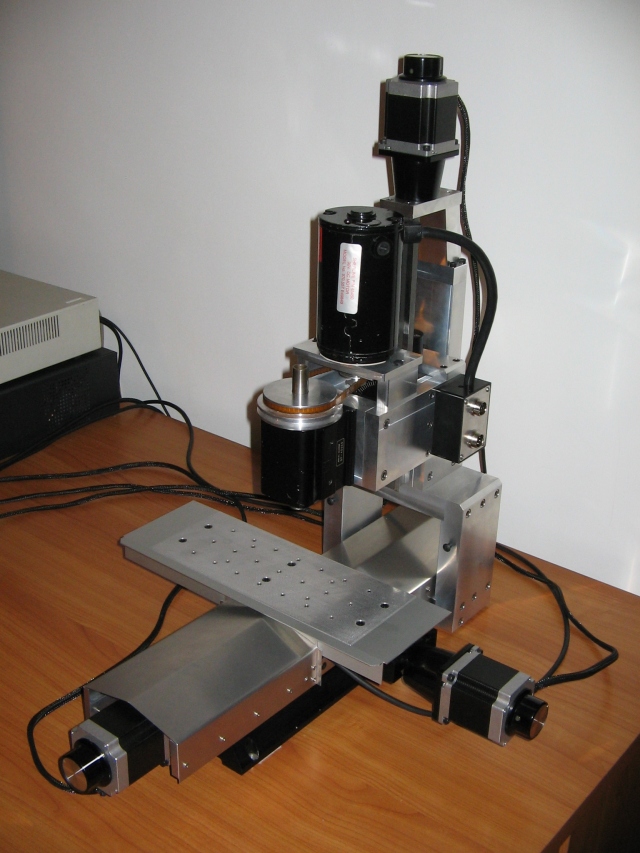

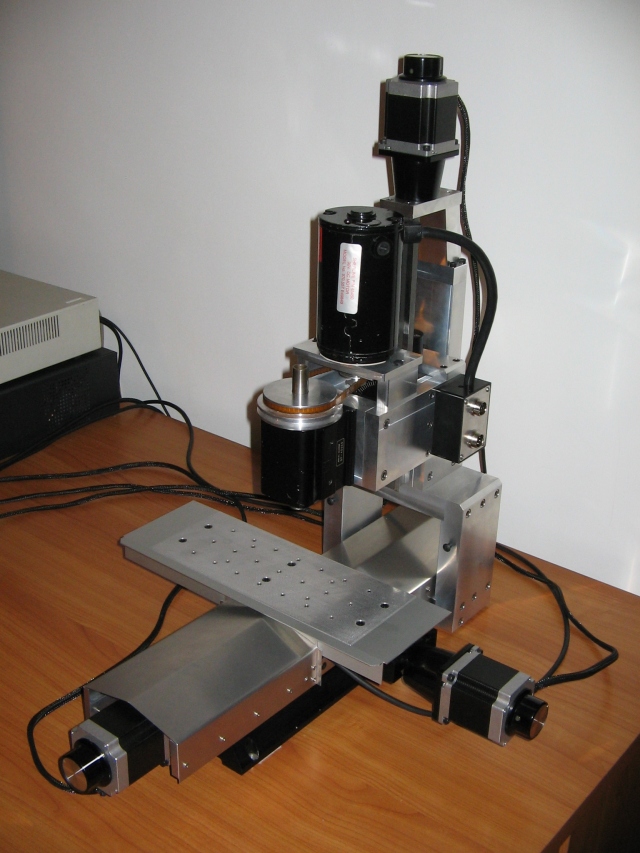

This thing is almost ready to cut. Now I’m working on the spindle controller; just a new plastic box and integrating a DigiSpeed board.

I guess the first thing I will cut will be a encoder wheel for the spindle.

I guess the first thing I will cut will be a encoder wheel for the spindle.

This thing is almost ready to cut. Now I’m working on the spindle controller; just a new plastic box and integrating a DigiSpeed board.

I guess the first thing I will cut will be a encoder wheel for the spindle.

I guess the first thing I will cut will be a encoder wheel for the spindle.

Incredible work…

One thing i want to ask.. Do you think z axis gib can handle that load?.. Seems quite heavy

Awesome work with the cover…. Complete escape from chips.

What i do to escape chips is i turn on vacuum with a brush at the end all the time while machinng.

What i learned is that machining dry will make dust aluminum particles that may be very harmful to health. They are very small to be seen and fly everywhere when spindle is turned on.

I stringly recommend vac. Even with coolant, after it dries up aluminum dust will be loose again..

Just my ideas. And keep up the good work dude!

Thanks. I have had no issues with z axis gib, but a larger saddle with straight gibs is in my wish-list. I agree, a vacuum and a brush are always required. The cover purpose is just to protect the ways and leadscrew; it makes easier to clean the chips but you should clean anyway. Something that I would really like is an integrated vacuum system on the headstock.

Thats a brilliant idea..! Gonna try that.

I guess ur right, sherline gibs are actually pretty dam good, i had doubts about them tho.

But after plenty of research, teflon is the way to go for al 7075 saddles…

I think they are pretty darn tough, cos i have 4″ chuck on my sherline mill and its kinda heavy, but still handles that well. Yes i know i use a chuck lol. Easy to change tools 🙂

I sometimes turn mill too 🙂

Well I think teflon it’s not rigid enough; maybe Delrin AF or Ertalite TX be more appropriate for that kind of application.